Smart Cross‐Bamboo

Jonas Hauptman, Assistant Professor of Industrial Design and Director of the Materials & Design Lab (MaD Lab), has been working in collaboration with Katie MacDonald and Kyle Schumann (former CAUS colleagues and now University of Tennessee Architecture Fellows) to research and develop contemporary bamboo building systems. The goal of their research is to develop an affordable, open source, digitally-enhanced system for manipulating bamboo, converting it into refined, modern, sustainable material systems at a variety of scales, from consumer to building products.

The potential benefits of bamboo as a rapidly-renewable, low-carbon, sustainable material are well established, yet bamboo remains underutilized globally due to its material irregularity, antiquated construction techniques, and deeply-rooted aesthetic stigmas in western culture. The team is working in three areas of bamboo research: grown, machined, and composited. This work has been included in recent conferences including the Architectural Research Centers Consortium ( ARCC:2019) the 4th International Sustainable Buildings Symposium as of this summer, and will be presented this fall at the Association for Computer Aided Design in Architecture (ACADIA).

Supported by a $3,000 Creativity + Innovation Strategic Growth Area Mini SEAD Grant, the team has recently completed a preliminary experiment by digitally manipulating the growing process of Madake Bamboo, in order to alter its transverse section into a curved shape. The eventual hope is to do this via computer control so as to create designed variation through growth. This project was in collaboration with Horticulture faculty Dr. Alex Niemiera with the support of several CAUS students. A special thanks goes to the MaD Lab summer build team for watering and documenting the project.

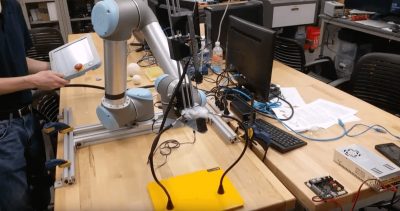

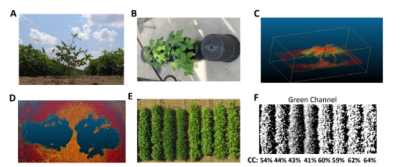

Another large ongoing project is the development of a generative, digitally-enhanced design and fabrication process for working with solid bamboo poles, commonly known as Iron Bamboo. The project focuses on the technical as well as semantic aspects of working with bamboo in regards to developing the built environment. The cross-disciplinary team is developing multiple fabrication processes and technologies for using a visual, noninvasive evaluation through 3D scanning and photographic analysis, as well as a 4-axis rotary CNC for the milling of unique joints in structural bamboo building components. Building on previous research and development, these discrete technologies will be synthesized, allowing designers to create intelligent parametric real-world buildings with streamlined user input. This work has also included the development of structural systems. Brooks Forest Products Center in the College of Natural Resources and Environment was instrumental in providing the technical support necessary for testing and analyzing planked Iron Bamboo. Nine months into this 18 month project cycle, which is funded by a $30,000 grant from the American Institute of Architects Upjohn Research Initiative, the team is currently embarking on the design-build of a full scale interior architecture installation at the Research and Demonstration Facility, with plans for it to be completed in late Fall of 2019.

Lastly, Hauptman and his architect collaborators are also pursuing research in the field of additive fabrication of composite bamboo. Working alongside Sustainable Biomaterials faculty Hindman and Hammett, the College of Natural Resources and Environment the work explores the potential of creating Smart Cross-Laminated Bamboo (SCLB). This unique construction material takes advantage of the best qualities of both Cross-Laminated Timber (CLT) and Structural Insulated Panels (SIPs). SCLB will utilize the naturally lightweight and hollow bamboo to form structural panels that can accommodate insulation and utilities within the thickness of the panel. The team is optimistic that by transforming the round, irregular bamboo into consistent tubes and eventually flat panels, new applications will be made possible within a Western context.

This project has very generous support from funded awards: the Arnold W. Brunner Grant awarded by the Center for Architecture, NY, NY, in the amount of $13,000; as well as a Major SEAD grant of $25,000 from VT’s Institute for Creativity, Arts, and Technology supported through a joint initiative from Creativity + Innovation Strategic Growth Area and the Intelligent Infrastructure for Human-Centered Communities Destination area.

In harnessing and maximizing the rapidly-renewable, low-carbon, sustainable properties of the bamboo grass, these research projects are poised to impact the world’s growing environmental challenges, particularly those wrought by the global building and construction industry. The application of digital technologies will help eliminate the current process of laborious manual evaluation and fabrication techniques associated with bamboo, allowing for regularized building stock with environmentally-preferable properties.

ICAT 2019-2020 Major Sead Grant

-

-

ICAT Center

-

- ICAT Project

-

ICAT Project

-

-

Idea-Challenge

-

-

-

-

-

Research

-