Towards a 3D Printing Loom

Multi-nozzle Fabrication of Large-Scale Performance Textiles

Traditional textile weaving, produced by industrial looms, knitting machines, and other long-used industrial machinery have mass produced textiles for clothing and other industries. Where these machines have excelled in terms of speed, the control and precision of their output is limited. 3D printing, on the other hand, offers tremendous amounts of control in the placement and geometry of a variety of materials by turning molten filaments of plastic into highly precise geometries, as seen in the examples of 3D printed fog harvesting materials shown in Figure 1. While a 3D printer offers an increased level of geometric control, it is encumbered by slower speeds: a single nozzle depositing molten material in a serially repeated pattern would take considerable time to complete, especially at a sufficient scale.

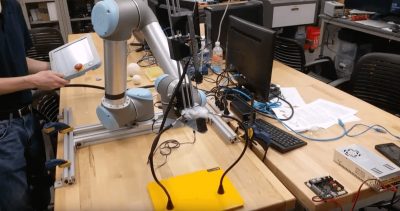

This research proposes creating a new 3D printing device capable of fabricating large-scale textile materials at high throughput by combining the speed of a loom with the precision of a 3D printer (Figure 2). The team, composed of an interdisciplinary group of domain experts, seeks to produce large-scale passive fog harvesting structures and other performance textiles through the design of such a custom machine: “Multi-nozzle 3D printer for large-scale performance textiles.” This machine would be constructed by combining two major components: (i) an industrial robotic arm connected to a computer-driven conveyor and (ii) a multi-nozzle deposition tool capable of printing up to 20 filaments at once. This novel system design would enable the rapid fabrication of larger 3D printed textile structures, as much as 2’ x 13’ long.